Belt Conveyor System

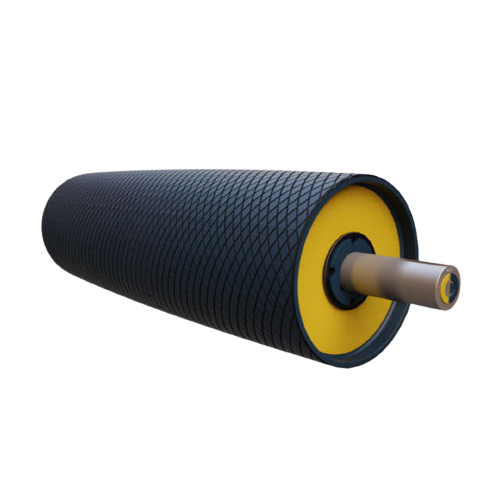

Conveyor Pulleys

Links Engineering Industries manufactures Heavy and Light duty Belt Conveyor Pulleys suitable for all types of working conditions. Pulley assembly dimensions and tolerances are based on IS specifications. Pulley shells are either made from standard heavy tubes or fabricated from steel plates. Depending upon the face width, two or three diaphragms are provided. Pulley shafts are of carbon steel and fully machined to precise tolerances. Straight or crowned faces are available in all combinations of diameters and face width. All types of pulley are available with various types of rubber lagging that can prevent slippage, wear & tear, and protection from foreign material.

CARRYING & RETURN IDLERS

Links Engineering Industries ensures achievement of operational success of belt conveyors, in a way, the shell is made from Mild Steel ERW black steel tube superseding IS: 9295 & IS 1239, pressed steel housing from CRCA sheet, the shaft of machined bright steel bar, a sealing system consisting of (back-seal, double labyrinth, moulded dust cover, a rain cap), single piece fabricated steel idler frame and rollers fitted with seize resistant ball bearings and supersedes IS:8598.

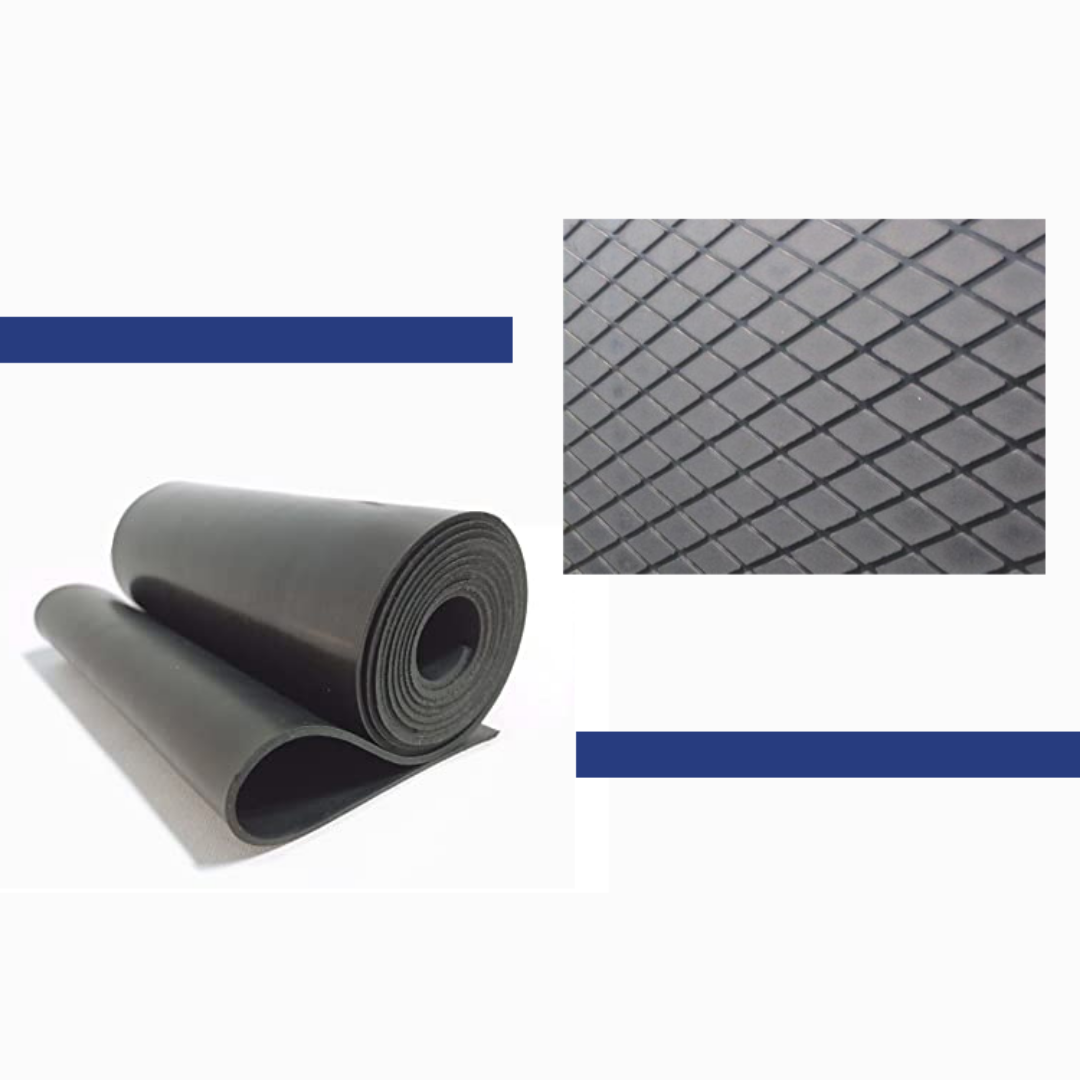

Lagging Sheet

Lagging sheet is used as a protective surface to improve and extend pulley life. It is applied to the pulley exterior, protecting the metal shell from wear and tear. The rubber diamond texture enhances friction between the belt and pulley, resulting in improved grip, better water shedding, and less belt slippage. It is cost effective and easily replaceable.

The pulley Laggings sheets come with CN bonding layers for better adhesion levels. The profiled patterns on the top surface, in diamond or square embossing improve belt grip and tracking on conveyors, while reducing belt wear.

Features & Benefits

- Reduces energy consumption

- Increases productivity

- High coefficient of friction

- Improves belt traction

- Reduces belt slippage

- No residue on pulley

- Increases belt and pulley life

- Minimize system downtime

- Reduces wear from abrasive materials

Benefits

- Easy to fit

- Outstanding wear and abrasion resistance

- Reduced adhesive use

- Minimises build-up on pulleys